Latest News

2022-04-24

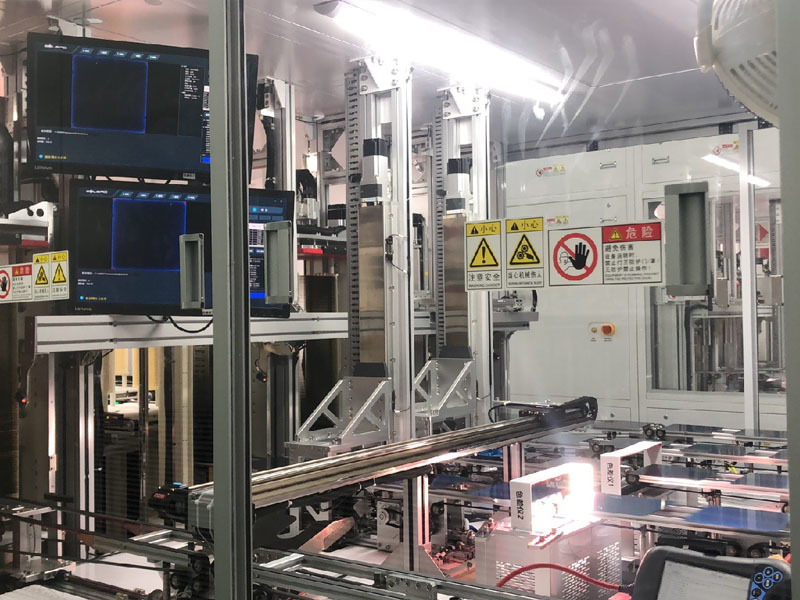

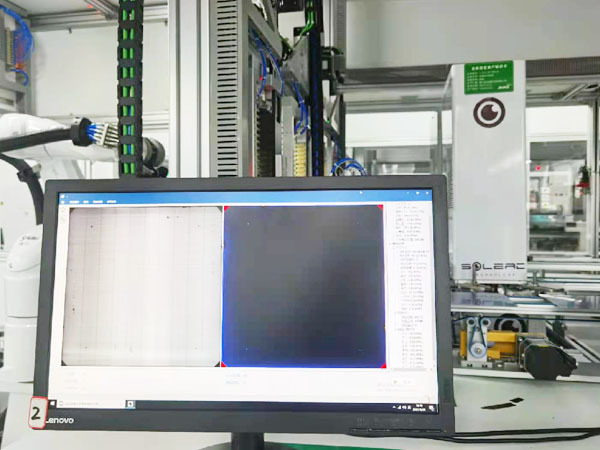

Color Appearance Inspection Equipment After SOLEAD Coating-Line Scan

Solead is committed to the field of machine vision, physical information systems and industrial Internet of Things

SOLEAD graphite boat testing equipment

Solead is committed to the field of machine vision, physical information systems and industrial Internet of Things

Solead is committed to the field of machine vision, physical information systems and industrial Internet of Things

Zhenjiang Solead Technology Co., Ltd.

Pioneer in bringing machine vision to the photovoltaic industry

Zhenjiang Solead Technology Co., Ltd. was established in 2014, with the traditional manufacturing industry information transformation as the core, is committed to machine vision solutions. At present, the business scope is mainly based on the research and development and industrialization of machine vision inspection products, software development and industrialization, focusing on the technology and product development of automated inspection equipment in the photovoltaic industry. The company is a pioneer in the introduction of machine vision into the photovoltaic industry, but also the introduction of artificial intelligence into the field of photovoltaic intelligent perception, the company's photovoltaic industry cell intelligent perception module has a high market share and praise rate in the industry.

Brand philosophy

At present, the company will open up new ideas, develop the intelligent production quality management mode of cell production in the photovoltaic industry, and open a new era of big data, full-line multi-node, intelligent and automated cell production.

Scientific and technological innovation

So far, it has applied for 37 invention patents and authorized 4 invention patents; Applied for and authorized 9 utility model patents; It has obtained 15 computer software copyrights, 5 scientific and technological new searches, 4 software product certificates in Jiangsu Province, 11 software product testing reports in Jiangsu Province, and 2 quality inspection reports. Since its establishment, it has been successfully approved as a private science and technology enterprise in Jiangsu Province, a small and medium-sized science and technology enterprise in Jiangsu Province, a software enterprise in Jiangsu Province, and a national high-tech enterprise.

2021/09/15

Organizations in the manufacturing industry are under more pressure than ever to increase output while maintaining high quality, productivity and reliability standards.

04-24

Organizations in the manufacturing industry are under more pressure than ever to increase output while maintaining high quality, productivity and reliability standards.

Production process control is considered a key success factor for the solar industry. However, this is only part of the favorable conditions for success: In order to fully optimize production and reduce costs, producers must take further steps to ensure that only defect-free materials are processed.

With the increase of labor costs, at the same time, in order to ensure the absolute quality of products, avoid product quality problems caused by many human factors, such as secondary pollution and sorting fragments. It is the future development trend of photovoltaic manufacturing technology to use machine vision inspection technology to replace manual labor to objectively and reliably monitor and sort the quality defects of silicon wafers and cells.

[According to the US "Military Aerospace" report on April 17, 2017] In April 2017, Canada's Teledyne DALSA launched the Linea 16k CLHS low-voltage system for flat panel displays, printed circuit boards, network inspection and general machine vision optoelectronic systems Cost line scan cameras.

Production process control is considered a key success factor for the solar industry. However, this is only part of the favorable conditions for success: In order to fully optimize production and reduce costs, producers must take further steps to ensure that only defect-free materials are processed.

With the increase of labor costs, at the same time, in order to ensure the absolute quality of products, avoid product quality problems caused by many human factors, such as secondary pollution and sorting fragments. It is the future development trend of photovoltaic manufacturing technology to use machine vision inspection technology to replace manual labor to objectively and reliably monitor and sort the quality defects of silicon wafers and cells.

[According to the US "Military Aerospace" report on April 17, 2017] In April 2017, Canada's Teledyne DALSA launched the Linea 16k CLHS low-voltage system for flat panel displays, printed circuit boards, network inspection and general machine vision optoelectronic systems Cost line scan cameras.

The products developed by the company have blossomed everywhere in the photovoltaic market and have become one of the important suppliers in the photovoltaic cell production industry.

The main customer groups include LONGi Green Energy Technology Co., Ltd., Tongwei Co., Ltd., trina Solar Energy Co., Ltd., a leading enterprise in the photovoltaic industry. The company's annual order volume is rising year by year, the sales network is also expanding, and the customer base is spread throughout the northwest, north China, south China and other places in China, as well as india, Vietnam, Malaysia, Singapore and other countries abroad.

Dedicated to so professional, Solead provide you with a full range of services and support

Search for the product or service you want to know about

Address: Building C25, Central R&D Zone, 99 Chuqiao Road, Zhenjiang New District, Jiangsu Province

E-mail: support@sydtech.cn

Mobile Station

Copyright © 2022 Zhenjiang Solead Technology Co., Ltd. Powered by www.300.cn 苏ICP备14042596号-1